The average feed conversion in U.S. broilers has been reduced to less than 1.75 pounds of feed per pound of broiler today and it is projected to be close to 1.5 by 2050, reported Michael Kidd, Ph.D., department head and professor, Center of Excellence for Poultry Science, University of Arkansas. Kidd gave the World Poultry Science Association lecture at the 2024 Poultry Science Association Annual Meeting in Louisville, Kentucky, on July 15.

Kidd’s presentation was titled “Global poultry nutrition challenges.” He used historical improvement trends in broiler performance along with research results and technological advances to highlight challenges and opportunities for the future of poultry nutrition.

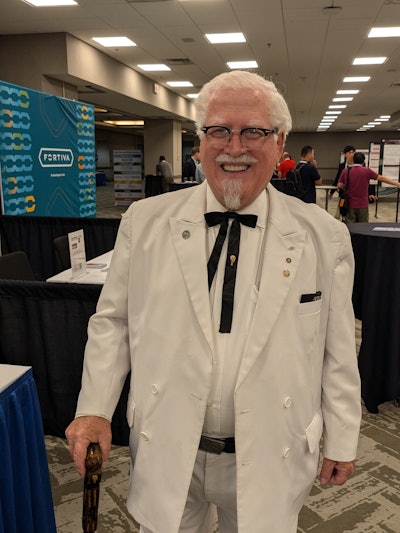

Broiler performance metrics have increased dramatically in the last few decades. For example, breast meat yield in 2024 is double what it was in 2001. Kidd said that the improvements will continue. He said that producers should be able to grow a 4.2-pound bird fast food cut up size birds in 26 days or less in 2050, which should please Colonel Sanders.

Challenges and opportunities

Kidd said that he expects poultry nutritionists to focus more on precision nutrition and that U.S. integrators now have a unique opportunity to focus on amino acids. He said that there has never been a better time for the U.S. poultry industry to work with the soybean crush facilities on efficiency because there are so many new plants, and they all conduct near infrared (NIR) spectroscopy on soybeans and the resulting meal. Nutritionists should work with their soybean meal supplier to obtain the data on individual loads of soybean meal to adjust ration formulations. “There is a $20 per ton opportunity if the NIR value for each load is shared with the feed mill,” Kidd said. This should provide sufficient incentive for soybean crush facilities to share this data.

Much of the research on vitamin and mineral needs of poultry is old and was conducted on birds that grew slower. Kidd said that we need more research on vitamin and mineral needs since sources are changing and requirements of the birds have potentially changed. He said that modelling is great, but that you need some data to start with.

Kidd said he thinks use non-linear equations for least cost formulation of rations offer a big opportunity for the poultry industry. He stressed that producers need to look at income over feed cost for the poultry products that they produce and not focus on minimizing feed conversion.